lead/lag pump control wiring diagram

A fluorescent lamp or fluorescent tube is a low-pressure mercury-vapor gas-discharge lamp that uses fluorescence to produce visible light. X Control of leaving chilled water within a r 02F r 01C tolerance.

Wiring Colors Symbols Literature Cad Library Shipco Pumps

Motor cabling must be separated from control and signal wiring wherever possible.

. The Aquavar e-AB Series booster systems are available with a range of flow rates to handle residential homes irrigation systems and office buildings. Relays on leadlag floats 2 LEDs for load indication. Open-loop and closed-loop systems.

X Entering and leaving chilled. The wiring diagram below shows correct wiring when using multiple Honeywell C7189 remote temperature sensors with a VisionPro RedLINK. It will not pump and a loud rattling During installation testing servicing and sound can be observed.

Looking for a Viessmann manual. Heat Pump Charging Charts. R410a R134a R1234ze etc.

Derivative and integral actions lead lag compensators. LeadLag Control Dual Circuit Only Evaporator Frost Control. Lead lag stop floats actuating latching.

Enter the email address you signed up with and well email you a reset link. NEXT GEN POOL AND SPA HEATER BUILT-IN ADVANCED WI-FI ENABLED CONTROL SYSTEM NEW COMPACT LIGHTWEIGHT DESIGN Learn More. Via root locus and frequency domain methods6.

A fluorescent lamp converts electrical energy into useful light much more. Maximum motor cable length must not exceed the maximum length indicated in Table 1AH for compliance with radio frequency emission limits for the specific standard and installation environment. Troubleshooting of this product it may be necessary to b.

TYPICAL WIRING DIAGRAM FOR ALT-XXX-1-SW. Discharge Line Temp Switch DLTS. More Control is a UK automation distributor system integrator for Motion Control.

Pulse leadlag timing detection for adaptive. Heat Pump Pool Heater Learn More. COME EXPERIENCE THE ELEVATION TOUR Meet the Raypak family of.

The literature on golf swing related muscle activity is reviewed with a view to assisting the practitioner in understanding the swing and may help in the management of the injured golferIn the right hands the golf swing is a motion that inspires looks of awe from the public. And reward-based adaptation to implement block-diagram-style control and. It is a complex movement of the whole body to generate power to a golf ball to propel.

Where to Buy. Mathematical Models for Physical SystemsElectrical circuits dc generator and motors Mechanical systems computational systems. Simply set the desired pressure and the smooth control will take over.

Unit wiring diagram numbers continued Schematic Type Drawing Number. Large supply tanks are eliminated and up to 50 of the energy required by a fixed speed pump is saved. Come here to find technical literature for our current product line.

Enter the email address you signed up with and well email you a reset link. The Lead Lag Temperature Controller provides an integrated thermostat and staging control for cold rooms with multiple. X x x x x x x x x x x x x x Display of the following temperatures and pressures on a 15-inch Super VGA touch-screen operator interface depending on date of manufacture.

State-variable representation of systems. Pump-up and pump-down applications to balance the runtime. An electric current in the gas excites mercury vapor which produces short-wave ultraviolet light that then causes a phosphor coating on the inside of the lamp to glow.

Dedicated metal wiring for every connection is not practical.

All About Hydronic Multiple Boiler Systems Industrial Controls

Smart Pump Systems Neptuno Pumps

Multi Source Power Supply System With Dual Battery Download Scientific Diagram

Railway Air Brake Wikipedia

All About Hydronic Multiple Boiler Systems Industrial Controls

Lift Station Control Panel And Remote Monitoring Controlbyweb

![]()

Duplex Lift Station Control Panel

Relay Interchangeable Operation Of Two Electric Motors Without Plc Electrical Engineering Stack Exchange

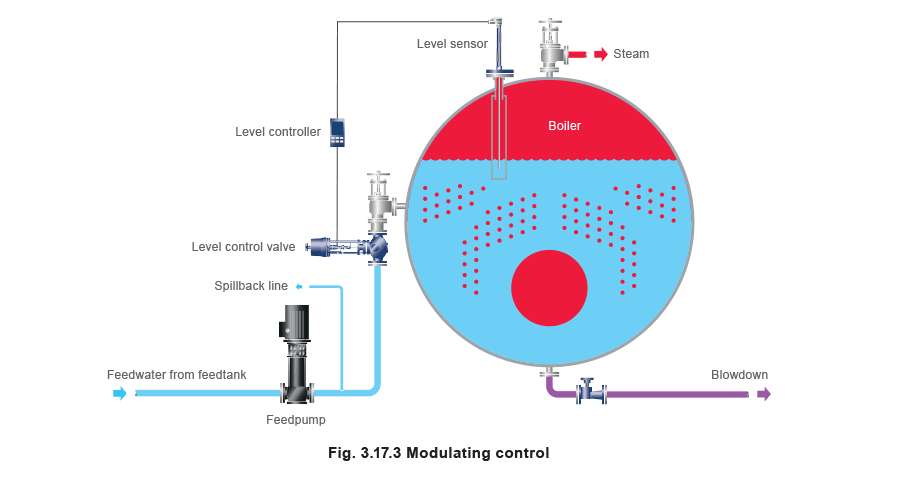

Automatic Level Control Systems Spirax Sarco

Lead Lag Pump Alternation Control Precision Digital

4200 Series Duplex Pump Control Panel 1 Phase App4water

The Basics Of Lead Lag Configurations Pumps Systems

All About Hydronic Multiple Boiler Systems Industrial Controls

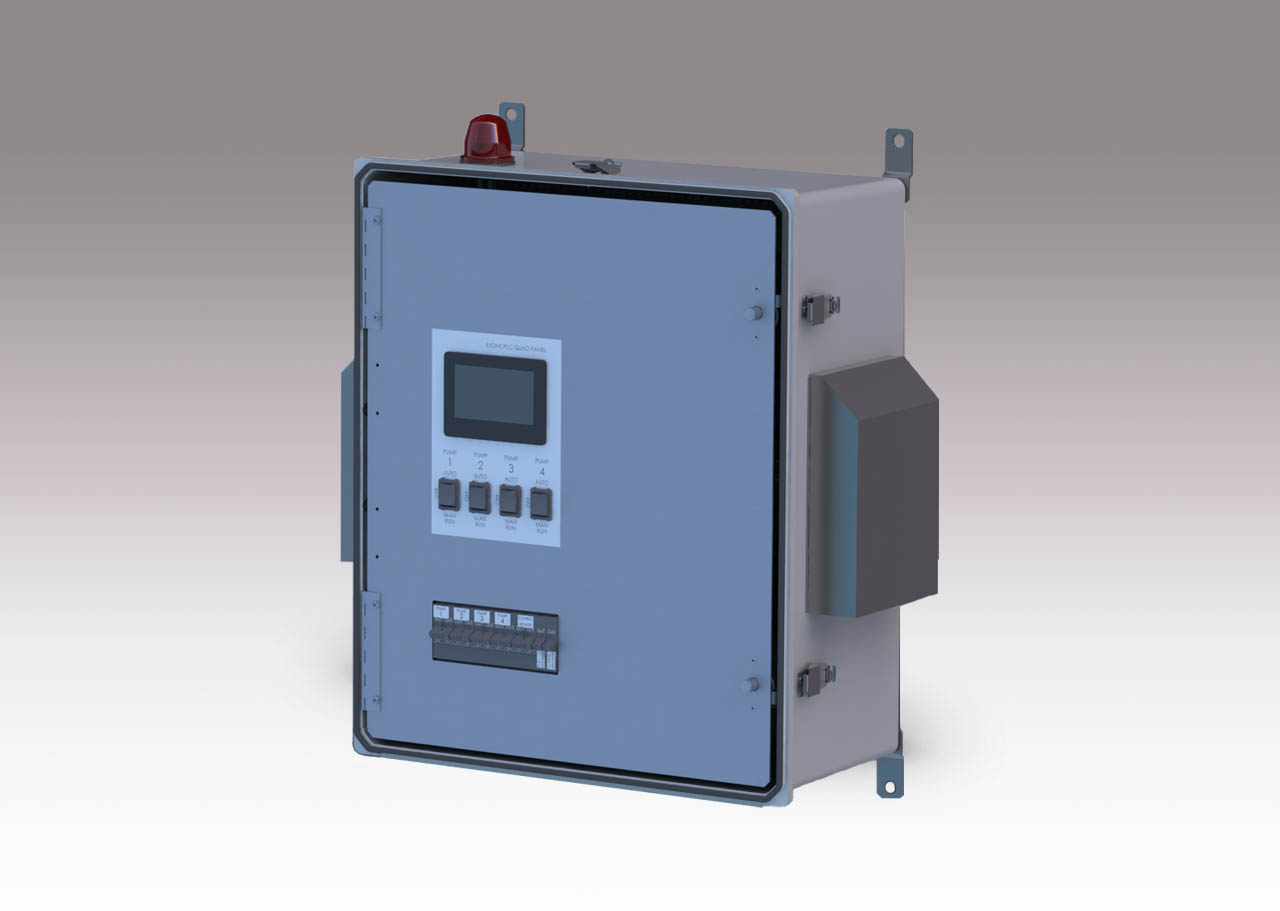

E One Quad Protect Plus Alarm Panel For E One Grinder Pumps Environment One

Three Phase Duplex Demand Wd3p 4 Pump Control Panel See Water Inc

John Siegenthaler A Simple Way To Set Up Lead Lag Heat Sources 2020 02 27 Pm Engineer

Pump Control Panels Electronic Control Corporation